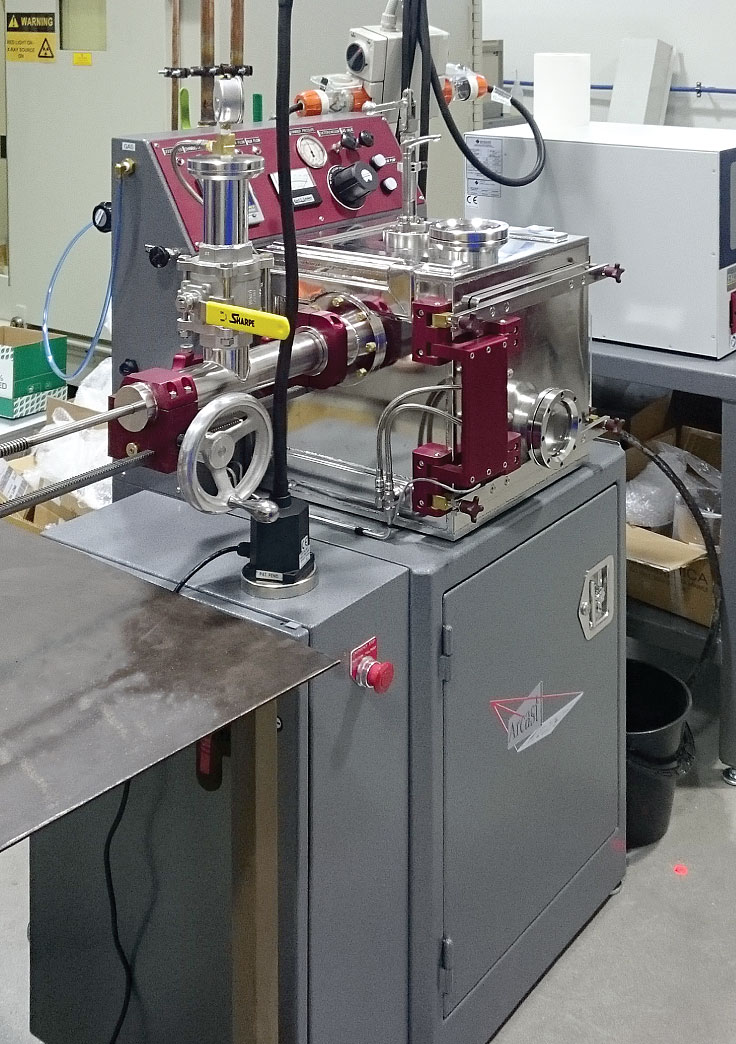

Ind 500 induction melting furnace

Specifications

Capacity

500g nominal

Melt temperature

1700⚬C

Crucible/hearth

Ceramic alumina (standard)

Graphite (optional)

Chamber

304 stainless

Induction coil

150kH 4kW

System requirements

Electrical:

Requires 1- and 3-Phase Power

208 – 240 VAC, 50/60 Hz 7kVA.

Water:

4 lpm below 30℃ @ 5bar

Gas:

Argon or other inert gas

The Arcast Mini Induction Melter offers the ability to melt, cast and rapidly solidify metal alloys of nominal 500 gram mass, using an induction ceramic or graphite crucible.

It offers the ability to melt and alloy metals at up to 1700⚬C. The furnace is enclosed in a stainless steel vacuum chamber and offers many standard options.

The standard options include:

- Melting and alloying cold furnace

- Tilt-casting with mold options

- Vacuum casting with mold options

- Centrifugal casting with mold options

- Free fall gas atomizer (for powder metallurgy)

There are also two vacuum options: medium (1E-2 mbar) and high (5E-6 mbar). All options are designed for quick cycle times and user friendly operation.

The intended use for the Induction Melter is to enable metallurgists and technicians to alloy nonreactive metals and cast them with the least running and capital costs, while maintaining a high engineering standard.